Energodiagnostika

Metal Magnetic Memory Method – a New Trend in Engineering Diagnostics

Traditional methods and means of diagnostics (ultrasonic inspection, magnetic particle inspection, X-ray) are oriented to detecting the already developed defects and by their designation can not prevent sudden fatigue damages of equipment, which are the main reasons of failures and sources of maintenance staff traumatism.

It is known that stress concentration (SC) zones, in which corrosion, fatigue and creep processes develop most intensively, are the main sources of damages occurrence in operating structures. Consequently, detecting SC zones is one of the most important tasks of equipment and structures diagnostics.

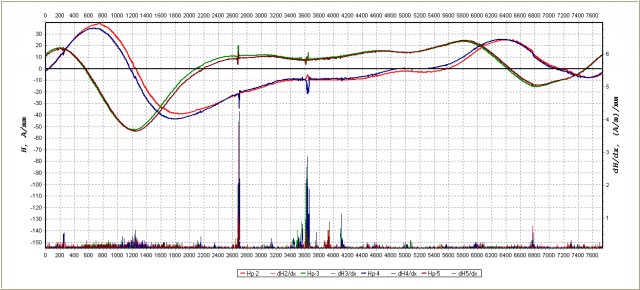

Metal magnetic memory is an aftereffect, which becomes apparent in the form of residual magnetization of products and welded joints metal formed in the course of their fabrication and cooling in a weak magnetic field or in the form of irreversible changing of products magnetization in stress concentration and damaging zones due to working loads. Variations of metal properties (corrosion, fatigue, creep) in SC zones are the processes preceding operating damaging. Metal magnetization, reflecting the actual stress-strained state of pipelines, equipment and structures, changes accordingly.

The MMM method unites the potential opportunities of non-destructive testing (NDT) and fracture mechanics due to which it has a number of significant advantages over other methods at inspection of industrial objects. The metal magnetic memory method is a non-destructive testing method based on registration and analysis of self-magnetic leakage fields (SMLF) distribution on products surface for determination of stress concentration zones, defects, metal and welded joints structure inhomogeneity.

Application of the Metal Magnetic Memory Method

Power Engineering - Engineering diagnostics, assessment of power equipment's basic elements residual life.

Boilers

- pipelines,

- vessels and apparatuses,

- welded joints, armature

Turbine equipment

- steam turbine rotors,

- steam turbine blades,

- support equipment.

Chemical Industry - Engineering diagnostics, residual life assessment

- Pipelines for various technological purposes

- Vessels and apparatuses

- Welded joints

- Armature

Oil and Gas complex - Engineering diagnostics, residual life assessment

- Oil and gas trunk pipelines

- Industrial pipelines

- Compressor plant equipment.

Metallurgy - Quality control of cast products and sections

- Rolling-mill machinery elements for various applications

- Finished products

- Support equipment

Railway Transport - Inspection and engineering diagnostics

- Rails

- Wheel pairs

- Automatic coupling elements

- Locomotive and car parts

- Support equipment

Sea Transport - Engineering diagnostics

- Power plant element

- Industrial pipelines

- Hoisting devices

- Support equipment

Aviation - Inspection and engineering diagnostics

- Power plant parts

- Undercarriage bolted joints

- Aircraft hull elements

Metal Structures - Inspection and engineering diagnostics

- Bridge structures

- High-rise structures

- Mine plants

- Drilling rigs

- Fastening members